Elektri- ja soojuse koostootmisseadmed

Pakume kõrge efektiivsusega maagaasi baasil töötavaid lokaalseid soojus- ja elektrienergia koostootmisseadmeid,

mis sobivad erinevat tüüpi hoonetesse, et katta nende energiavajadus.

Väiksemad ja suuremad korterelamud

Tootmis- ja laohooned

Koolid ja lasteaiad

Eramud

Spordihooned

Lokaalse koostootmisjaama projekteerimisel lähtutakse eelkõige hoone soojuskoormusest, kuna koostootmisjaama peamine eesmärk on katta kogu hoone soojusenergia vajadus ning kõrvalproduktina toota ka elektrit. Tõusutrendis olevad energia hinnad panevad aina enam mõtlema selle peale kuidas säilitada minimaalsed energiakulud ka tulevikus. Elektri- ja soojusenergia koostootmise efektiivsus ulatub kuni 96%-ni.

Piltlikult võib suurte elektrijaamade tootmisprotsessi võrrelda suure õunaga, millest võetakse vaid üks amps ja ülejäänud õun visatakse ära. Elektri tootmisel tekkivat jääksoojust ei kasutata otstarbekalt ära, mistõttu läheb suur osa elektrijaamas toodetud energiast kaotsi. Samal ajal aga võib elektri ja soojuse koostootmisprotsessi võrrelda mahlase õunaga, mis süüakse kuni südamikuni ära. Tootes energiat lokaalse soojus- ja elektrienergia tehnoloogiaga kasutatakse ära ka jääksoojus, mis võimaldab säästa nii keskkonda kui ka raha.

Seadmed

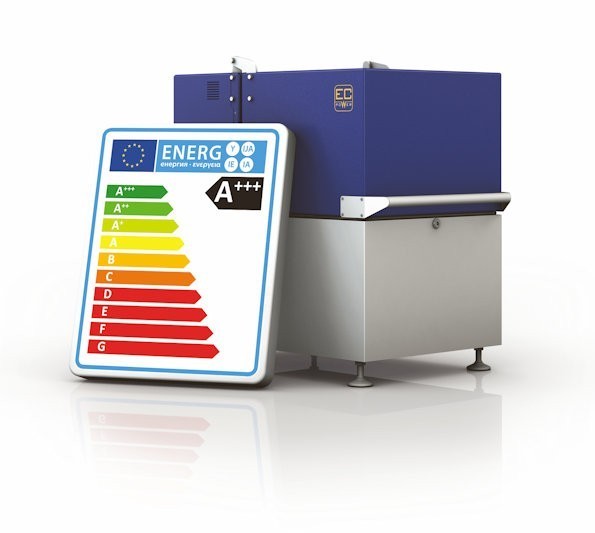

Oleme EC POWER A/S koostootmisseadmete ametlik esindaja Baltikumis. Täisautomaatsed ja kvaliteetsed EC POWER seadmed on toodetud Taanis.

XRGI 6 ja XRGI 9 on väiksemad elektri- ja soojusenergia koostootmisseadmed, mis sobivad installeerimiseks eramutesse, väiksematesse korterelamutesse.

XRGI 15, XRGI 20, XRGI n sobivad suuremate tarbijate energiavajaduse katmiseks, näiteks tootmishooned, hotellid, korterelamud, spordihooned, kaubanduskeskused jms.

Seadmeid on võimalik kombineerida vastavalt sellele, milline on hoone energiavajadus.

Rohkem infot: https://www.ecpower.eu/en/

XRGI 6

| XRGI® system | XRGI® 6 without condensing technology1 | XRGI® 6 with condensing technology1 | ||||||

| Modules | Power Unit, iQ10-Control Panel, Q20-Heat Distributor | Power Unit, iQ10-Control Panel, Q20-Heat Distributor + Condensing and exhaust gas heat exchanger BW4+ | ||||||

| Seasonal space heating energy efficiency class2 | A+++ | A+++ | ||||||

| Seasonal space heating energy efficiency; HCV 2,3,4 ηs | 170% | 198% | ||||||

| Power modulation* | 50% | 75% | 100% | 50% | 75% | 100% | ||

| Electrical output, modulating* | kW | 3.0 | 4.5 | 6.0 | 3.0 | 4.5 | 6.0 | |

| Thermal output, modulating* | kW | 8.1 | 10.1 | 12.4 | 9.3 | 11.7 | 14.4 | |

| Electrical efficiency in accordance with LCV4 | % | 24.8 | 28.5 | 30.1 | 24.8 | 28.5 | 30.1 | |

| Thermal efficiency in accordance with LCV4 | % | 67.6 | 64.5 | 62.3 | 77.5 | 74.5 | 72.3 | |

| Total efficiency in accordance with LCV4 | % | 92.4 | 93.0 | 92.4 | 102.3 | 103.0 | 102.4 | |

| Flow temperature, constant | °C | ~ 80 | ~ 80 | |||||

| Return temperature, variable | °C | 5-70 | 5-70 | |||||

| Sound pressure level (based on surroundings) | dB(A) | 49 | 49 | |||||

| Fuels | gas | natural gas (all qualities), propane, butane | natural gas (all qualities), propane, butane | |||||

| Emissions (test data at full load) | CO < 150 | mg/Nm3 | 12 | 13 | ||||

| NOx, pond, HCV3,4 < 240 | mg/kWh | 230 | 217 | |||||

| Dimensions, W x H x D | mm | 640 x 960 x 930 | 640 x 960 x 930 | |||||

| Footprint | M2 | 0.59 | 0.59 | |||||

| Weight | Kg | 440 | 440 | |||||

| Service interval (operating hours) | hours | 10 000 | 10 000 | |||||

* Continuous modulation in power-controlled mode

1 Return temperatures as per EN 50465 2015 7.6.1: Without condensing technology 47 °C, with condensing technology 30 °C.

2 This values are based on independent, certified and authorised inspection bodies. Test reports are available upon request.

3 The values were rounded in accordance with the requirements governing product data sheets by Regulation (EU) No. 811/2013; 813/2013

4 HCV = higher calorific value, LCV = lower calorific value

Deviations in values depend on the ambient and operating conditions, tolerance +/- 5 %. Subject to technical modifications, deviations from design and errors.

XRGI 9

| XRGI® system | XRGI® 9 without condensing technology1 | XRGI® 9 with condensing technology1 | ||||||

| Modules | Power Unit, iQ10-Control Panel, Q20-Heat Distributor | Power Unit, iQ10-Control Panel, Q20-Heat Distributor + Condensing and exhaust gas heat exchanger BW4+ | ||||||

| Seasonal space heating energy efficiency class2 | A+++ | A+++ | ||||||

| Seasonal space heating energy efficiency; HCV 2,3,4 ηs | 169% | 199% | ||||||

| Power modulation* | 50% | 75% | 100% | 50% | 75% | 100% | ||

| Electrical output, modulating* | kW | 4.5 | 6.8 | 9.0 | 4.5 | 6.8 | 9.0 | |

| Thermal output, modulating* | kW | 12.4 | 15.7 | 20.1 | 14.2 | 18.4 | 23.3 | |

| Electrical efficiency in accordance with LCV4 | % | 25.4 | 28.5 | 29.3 | 25.4 | 28.5 | 29.4 | |

| Thermal efficiency in accordance with LCV4 | % | 70.1 | 66.5 | 65.6 | 80.1 | 77.4 | 76.5 | |

| Total efficiency in accordance with LCV4 | % | 95.5 | 95.1 | 94.9 | 105.5 | 105.9 | 105.9 | |

| Flow temperature, constant | °C | ~ 80 | ~ 80 | |||||

| Return temperature, variable | °C | 5-70 | 5-70 | |||||

| Sound pressure level (based on surroundings) | dB(A) | 49 | 49 | |||||

| Fuels | gas | natural gas (all qualities), propane, butane | natural gas (all qualities), propane, butane | |||||

| Emissions (test data at full load) | CO < 150 | mg/Nm3 | 33 | |||||

| NOx, pond, HCV3,4 < 240 | mg/kWh | 25 | ||||||

| Dimensions, W x H x D | mm | 640 x 960 x 930 | 640 x 960 x 930 | |||||

| Footprint | M2 | 0.59 | 0.59 | |||||

| Weight | Kg | 440 | 440 | |||||

| Service interval (operating hours) | hours | 10 000 | 10 000 | |||||

* Continuous modulation in power-controlled mode

1 Return temperatures as per EN 50465 2015 7.6.1: Without condensing technology 47 °C, with condensing technology 30 °C.

2 This values are based on independent, certified and authorised inspection bodies. Test reports are available upon request.

3 The values were rounded in accordance with the requirements governing product data sheets by Regulation (EU) No. 811/2013; 813/2013

4 HCV = higher calorific value, LCV = lower calorific value

Deviations in values depend on the ambient and operating conditions, tolerance +/- 5 %. Subject to technical modifications, deviations from design and errors.

XRGI 15

| XRGI® system | XRGI® 15 without condensing technology1 | XRGI® 15 with condensing technology1 | ||||||

| Modules | Power Unit, iQ15-Control Panel, Q80-Heat Distributor | Power Unit, iQ15-Control Panel, Q80-Heat Distributor + Condensing and exhaust gas heat exchanger BW8+ | ||||||

| Seasonal space heating energy efficiency class2 | A+++ | A+++ | ||||||

| Seasonal space heating energy efficiency; HCV 2,3,4 ηs | 163% | 192% | ||||||

| Power modulation* | 50% | 75% | 100% | 50% | 75% | 100% | ||

| Electrical output, modulating* | kW | 7.3 | 10.9 | 14.5 | 7.3 | 10.9 | 14.5 | |

| Thermal output, modulating* | kW | 21.4 | 26.5 | 30.8 | 24.8 | 31.4 | 36.7 | |

| Electrical efficiency in accordance with LCV4 | % | 23.9 | 27.0 | 29.5 | 23.9 | 27.1 | 29.3 | |

| Thermal efficiency in accordance with LCV4 | % | 69.8 | 65.4 | 62.3 | 81.3 | 77.9 | 73.9 | |

| Total efficiency in accordance with LCV4 | % | 93.7 | 92.4 | 91.8 | 105.2 | 105.0 | 103.2 | |

| Flow temperature, constant | °C | ~ 85 | ~ 85 | |||||

| Return temperature, variable | °C | 5-75 | 5-75 | |||||

| Sound pressure level (based on surroundings) | dB(A) | 53 | 53 | |||||

| Fuels | gas | natural gas (all qualities), propane, butane | natural gas (all qualities), propane, butane | |||||

| Emissions (test data at full load) | CO < 150 | mg/Nm3 | 93 | 97 | ||||

| NOx, pond, HCV3,4 < 240 | mg/kWh | 209 | 184 | |||||

| Dimensions, W x H x D | mm | 750 x 1,170 x 1,120 | 750 x 1,170 x 1,120 | |||||

| Footprint | M2 | 0.84 | 0.84 | |||||

| Weight | Kg | 580 | 580 | |||||

| Service interval (operating hours) | hours | 8500 | 8500 | |||||

* Continuous modulation in power-controlled mode

1 Return temperatures as per EN 50465 2015 7.6.1: Without condensing technology 47 °C, with condensing technology 30 °C.

2 This values are based on independent, certified and authorised inspection bodies. Test reports are available upon request.

3 The values were rounded in accordance with the requirements governing product data sheets by Regulation (EU) No. 811/2013; 813/2013

4 HCV = higher calorific value, LCV = lower calorific value

Deviations in values depend on the ambient and operating conditions, tolerance +/- 5 %. Subject to technical modifications, deviations from design and errors.

XRGI 20

| XRGI® system | XRGI® 20 without condensing technology1 | XRGI® 20 with condensing technology1 | ||||||

| Modules | Power Unit, iQ20-Control Panel, Q80-Heat Distributor | Power Unit, iQ20-Control Panel, Q80-Heat Distributor + Condensing and exhaust gas heat exchanger BW8+ | ||||||

| Seasonal space heating energy efficiency class2 | A+++ | A+++ | ||||||

| Seasonal space heating energy efficiency; HCV 2,3,4 ηs | 213% | 247% | ||||||

| Power modulation* | 50% | 75% | 100% | 50% | 75% | 100% | ||

| Electrical output, modulating* | kW | 10.0 | 15.0 | 20.0 | 10.0 | 15.0 | 20.0 | |

| Thermal output, modulating* | kW | 26.1 | 31.4 | 38.7 | 29.3 | 35.9 | 44.7 | |

| Electrical efficiency in accordance with LCV4 | % | 26.9 | 31.1 | 32.7 | 26.9 | 31.1 | 32.7 | |

| Thermal efficiency in accordance with LCV4 | % | 70.4 | 65.4 | 63.4 | 78.8 | 74.6 | 73.2 | |

| Total efficiency in accordance with LCV4 | % | 97.3 | 96.5 | 96.1 | 105.7 | 105.7 | 105.9 | |

| Flow temperature, constant | °C | ~ 85 | ~ 85 | |||||

| Return temperature, variable | °C | 5-75 | 5-75 | |||||

| Sound pressure level (based on surroundings) | dB(A) | 49 | 49 | |||||

| Fuels | gas | natural gas (all qualities), propane, butane | natural gas (all qualities), propane, butane | |||||

| Emissions (test data at full load) | CO < 150 | mg/Nm3 | 15 | 26 | ||||

| NOx, pond, HCV3,4 < 240 | mg/kWh | 19 | 10 | |||||

| Dimensions, W x H x D | mm | 750 x 1170 x 1120 | 750 x 1170 x 1120 | |||||

| Footprint | m2 | 0.84 | 0.84 | |||||

| Weight | Kg | 680 | 680 | |||||

| Service interval (operating hours) | hours | 6000 | 6000 | |||||

* Continuous modulation in power-controlled mode

1 Return temperatures as per EN 50465 2015 7.6.1: Without condensing technology 47 °C, with condensing technology 30 °C.

2 This values are based on independent, certified and authorised inspection bodies. Test reports are available upon request.

3 The values were rounded in accordance with the requirements governing product data sheets by Regulation (EU) No. 811/2013; 813/2013

4 HCV = higher calorific value, LCV = lower calorific value

Deviations in values depend on the ambient and operating conditions, tolerance +/- 5 %. Subject to technical modifications, deviations from design and errors.

XRGI n

XRGI seadmed ei ole mõeldud kasutamiseks ainult eraldiseisvate süsteemidena, nende mooduldisain võimaldab neid ka paralleelselt ühendada. Paralleelselt ühendatud seadmeid on võimalik väga paindlikult ja säästlikult juhtida, tarnides elektrit ja soojust vastavalt vajadusele.

Koostootmisseadmete komponendid

Koostootmisseadmete peamised komponendid:

- Koostootmisagregaat

- Soojusvaheti

- Kontrollpaneel

- Soojussalvesti ja selle kontrollseade

- Koormuse jagaja